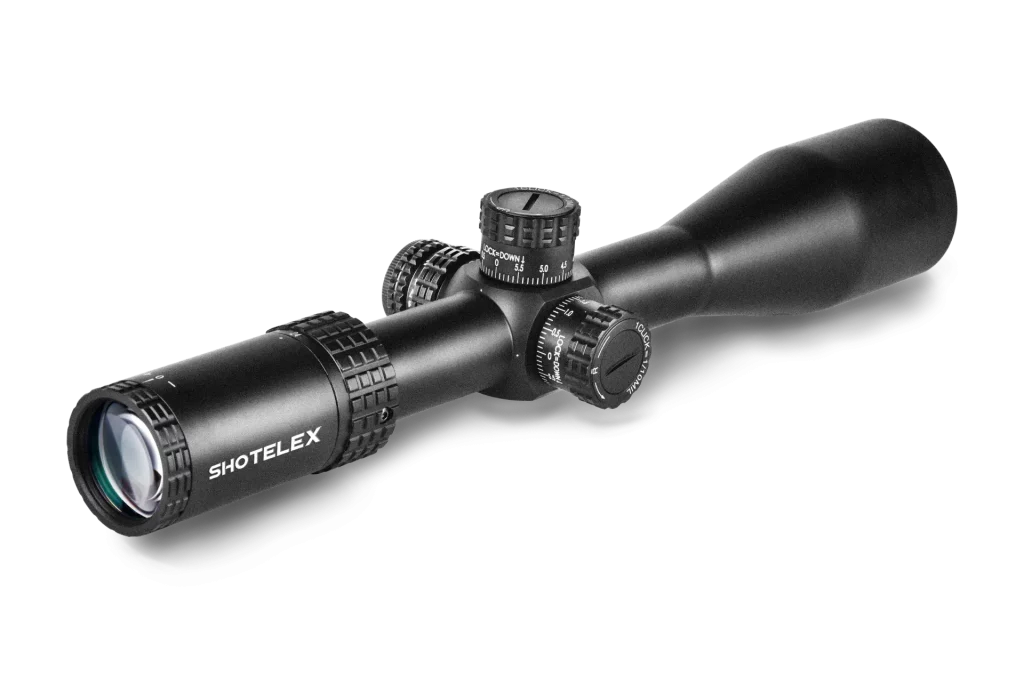

OEM vs. ODM Rifle Scopes: Which Model Is Better for Your Business?

In today’s competitive optics market, rifle scopes are no longer just about magnification and glass quality—they’re about branding, differentiation, and speed to market. For distributors, outdoor brands, and tactical equipment companies, one key strategic decision shapes everything that follows:

Do you choose OEM or ODM?

Both models are widely used in the rifle scope industry, but they serve very different business goals. Understanding the difference—and choosing the right one—can determine how fast you grow, how strong your brand becomes, and how profitable your product line will be.

Let’s break it down.

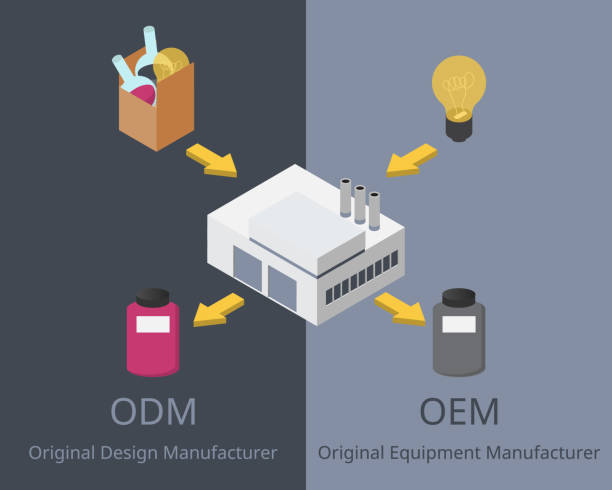

What is OEM and ODM?

Before we begin analyzing advantages and disadvantages we must define the specific meanings of these terms which exist in the optics industry. The two parties who own the Intellectual Property rights and design rights create the main distinction between these two options.

1. OEM (Original Equipment Manufacturer)

In the OEM model, you are the designer, and the factory is the executor. You provide the factory with detailed optical system drawings, mechanical structural designs, 3D models of the exterior, and even specific coating parameters for each lens. The factory’s role is to use its equipment and labor to turn your blueprints into reality. This means the resulting scope is unique, and the intellectual property belongs entirely to you.

2. ODM (Original Design Manufacturer)

In the ODM model, the factory is both the designer and the manufacturer. The factory invests in R&D based on their understanding of the market to create mature, ready-made products (often called “white label” products). You simply select a model from the factory’s catalog, make minor adjustments (such as changing the knob style, printing your logo, or customizing the packaging), and sell it under your brand.

The OEM Model: Building a Competitive Moat

If you want your brand to stand out in a saturated market, or if your target customers are professional shooters demanding specific performance, OEM is often the necessary path.

The biggest reason to choose OEM is differentiation. You can design a reticle with unique ballistic calculation features or develop turrets with a specialized locking mechanism. While competitors are selling generic products, your scope will possess an irreplaceability in both aesthetics and performance. This technical barrier is the best way to protect your profit margins.

However, the barriers to entry for OEM are significant.

- R&D Investment: You need a team of professional optical engineers or must pay high third-party design fees.

- Tooling Fees: Opening new molds for the scope body and internal mechanisms can cost tens of thousands of dollars.

- Minimum Order Quantity (MOQ): Factories usually require a high MOQ (e.g., 500 or 1,000 units) to amortize the cost of setting up the production line.

- Long Cycle: From drawing confirmation to prototyping, testing, and final mass production, the process typically takes 12 to 24 months.

OEM is suitable for well-funded companies with R&D capabilities that are focused on long-term brand building.

The ODM Model: Balancing Speed and Efficiency

For most startups or small-to-medium distributors, the ODM model offers a more pragmatic business route.

The biggest appeal of ODM is speed. Since the product has already been developed and tested by the factory, you skip the lengthy development cycle. You can often go from order to market launch in just 1 to 3 months. Additionally, because there are no tooling or R&D fees, the upfront capital requirement is much lower, and MOQ requirements are often more flexible. This allows businesses to validate the market quickly. For instance, Shotelex’s ODM catalog offers a range of field-tested optical solutions, helping our partners reduce their time-to-market to under 8 weeks.If a model doesn’t sell well, you can switch to another with very little cost.

The convenience of ODM is a double-edged sword. Since you can easily procure this product, so can your competitors. The market may become flooded with scopes that look and perform almost identically, differing only by the logo. This often leads to price wars, compressing your profit margins. Furthermore, because the core technology is controlled by the factory, you may be more passive when dealing with complex technical support issues.

ODM is suitable for companies looking to enter the market quickly, fill gaps in a mid-to-low-end product line, or those focusing on marketing rather than R&D.

The Intuitive Comparison Between The Two

| Dimension | OEM Model | ODM Model |

| R&D Investment | High (Requires own design team) | Very Low (Relies on factory solutions) |

| MOQ | High (Usually 500+ PCS) | Flexible (Usually 100+ PCS) |

| Differentiation | Very Strong (Unique, exclusive) | Weak (Logo/Packaging only) |

| Time-to-Market | Slow (12–24 Months) | Fast (1–3 Months) |

| Intellectual Property | Owned by Brand | Owned by Factory |

There is no absolute better between OEM and ODM, only what is more suitable for your current situation.

Whether you choose to leverage Shotelex’s mature ODM technology for a quick market entry, or you plan to utilize our engineering team for an OEM project to build a unique flagship product, Shotelex is ready to be your trusted manufacturing partner.Still hesitating on which model to choose? Contact the Shotelex team today for a free consultation and project assessment.